AT UNILEVER

In September, Consumer Insight Consulting had the great pleasure to once again organize sensory workshops at Unilever company in Poznań. The Production Plant is one of the largest Unilever factories producing food and it produces about 800 different products (fixes, sauces, soups, mealkits, pasta, ketchups, mayonnaises) under the brands Knorr, Hellmann’s, Unox, Amino, Bertolli, Calvé, Amora, Kuner. The company has many years of experience and has been focusing on the highest standards related to the production process and quality.

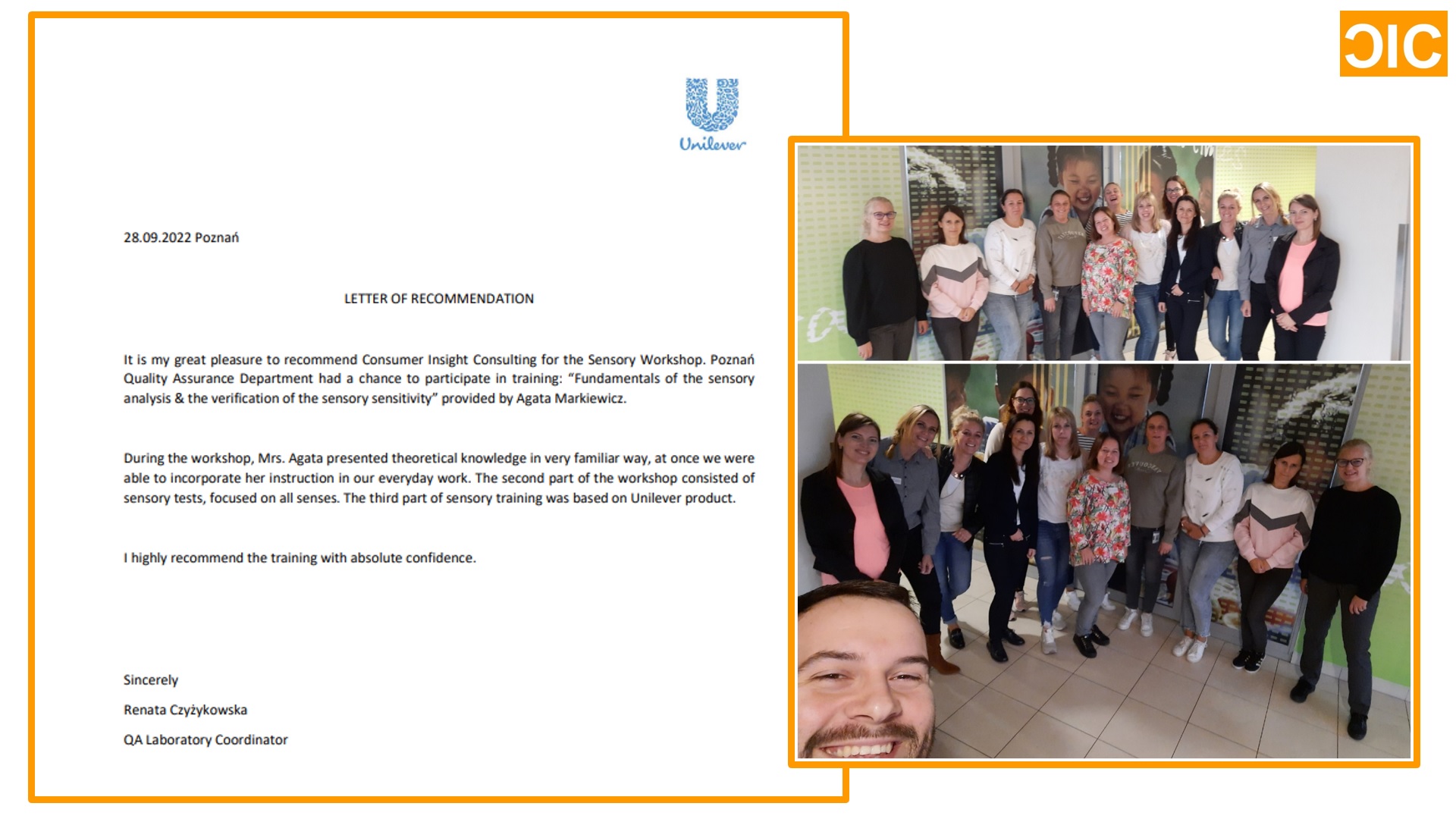

Sensory workshops were organized for the Quality Assurance Department at the invitation of Renata Czyżykowska, QA Laboratory Coordinator at Unilever.

Is it worth participating in our sensory workshops?

Below are the recommendations received from Mrs. Renata Czyżykowska, QA Laboratory Coordinator (in the original), who also participated in the workshop:

„It is my great pleasure to recommend Consumer Insight Consulting for the Sensory Workshop. Poznań Quality Assurance Department had a chance to participate in training: “Fundamentals of the sensory analysis & the verification of the sensory sensitivity” provided by Agata Markiewicz.

During the workshop, Mrs. Agata presented theoretical knowledge in very familiar way, at once we were able to incorporate her instruction in our everyday work. The second part of the workshop consisted of sensory tests, focused on all senses. The third part of sensory training was based on Unilever product.

I highly recommend the training with absolute confidence.”

During the “sensory workshops“, participants:

1) get acquainted with the topic of sensory analysis and its basic concepts,

2) get to know the correct rules of conducting organoleptic evaluation in theory and practice (the good practices of conducting sensory tastings),

3) participated in sensory tests aimed at verifying the individual sensory sensitivity of individual employees concluded with an individual assessment with recommendations.

Why is it worth carrying out regular sensory tests checking the sensory sensitivity among your employees?

The answer is simple. If you care about the proper quality control of the offered products, employees should regularly undergo sensory tests verifying their sensory ability (I recommend at least once a year).

In order to assess the products’quality, an organoleptic assessment is made using human senses (sight, smell, taste, touch, hearing). In this way, sensory discriminants are investigated, which are one of the main measures of food quality. Sensory attributes: visual, flavour and aroma of products influence the consumer’s perception of the product and, consequently, are critical factors determining the choice of food, chemical products, tobacco products etc. This assessment is made by the employees.

And here it should be remembered that people have different sensory predispositions, and among them there are people who, due to very low sensory sensitivity or certain limitations, such as colour blindness and taste blindness, should not make an organoleptic evaluation of products. Such people are not able to properly assess the product’s quality but for some reasons still often participate in tastings and make decisions.

Colour vision deficiency, commonly known as colour blindness, is a colour recognition disorder. In humans, it manifests itself as the inability to perceive differences between some or all of the colours that are normally perceived by other people. Colour vision deficiency is usually a congenital, genetically determined defect inherited recessively in conjunction with the X chromosome. Therefore, it affects men much more often (approx. 8%) than women (approx. 0.5%). The disorder can also be the result of damage to the visual tract from the retina to the cortex of the brain, as well as the side effect of drugs or chemicals.

The same is the case with taste blindness. A person with this disorder is unable to partially or completely distinguish individual tastes while eating something. These disorders lead to a complete abolition of the taste sensation, but also to the weakening or intensification of the perception of taste stimuli. Some of the causes of this problem lead to a transient taste disturbance, while others may lead to a permanent loss of taste.

Nowadays, it should be also remembered that, unfortunately, some people recovering from COVID-19 often suffer from long-term disturbances of the senses and they experience fake smells and tastes. Among them there are those who struggle for a long time with dysosmia, that is, impairment or a change in the perception of olfactory sensations. For example, they complain that the meat “smells like petrol”, they smell “rotting apples” when drinking prosecco. There are much more odour disorders, according sientists and doctors, after examination COVID-19 survivors. Sometimes odour disorders can be so strong that they effectively hinder normal functioning.

In order to eliminate such people from the decision-making process in matters of product quality, sensory tests for sensory sensitivity are carried out. Thanks to the tests, we can select people with the correct sensory abilities and thus, if possible for a given company, create the best possible product evaluation team, ensuring that a correct organoleptic assessment is made, which translates into product quality at every stage of its cycle.

However, this does not mean that people with very low sensory sensitivity or limitations should be completely excluded from the organoleptic evaluation, but their opinion should be neither crucial nor decisive.

You can read more about it here:

If you are also thinking about introducing changes in your company in terms of tasting sessions & assessing the products, you would like to organize similar sensory workshops in your premises as at Unilever company, in Poland or abroad, please contact us. The sensory workshops can also be led in English.